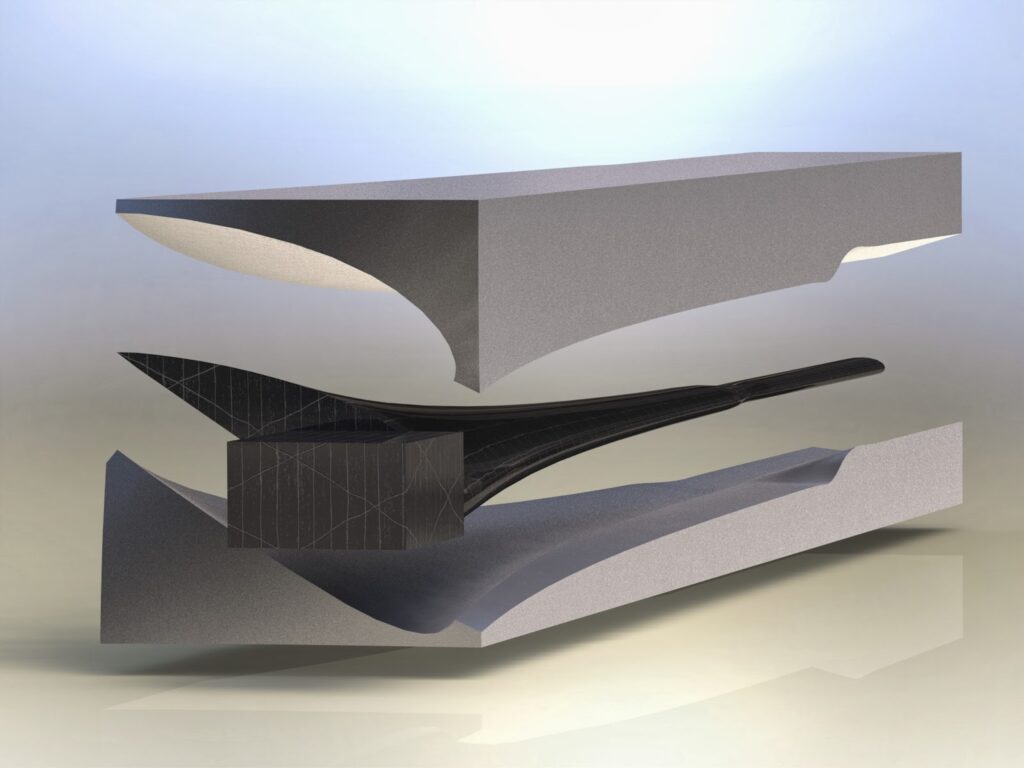

Turbine blades have a complex geometry and contain many areas of double curvature during the Manufacturing of Turbine Blades. Therefore the blades have to be precisely manufactured by the precision casting process of investment casting, also known as the ‘lost wax process’.

Ceramic cores for the cooling channels are positioned within a master mould pattern. Wax is then injected into the mould cavity to produce a preform of the turbine blade. Pinning wires are then pressed through the wax to butt against the ceramic cores within the preform. Next, the preform is coated with multiple layers of ceramic, ultimately forming a thick casing around the preform with the pinning wires embedded in it. The assembly is heated to melt out the wax and then tired to strengthen the ceramic. The result is a ceramic shell mould containing a complex ceramic core pattern which is held in position by pinning wires anchored in the ceramic shell. Finally, the mould assembly is preheated prior to casting the turbine blade during the process of Manufacturing of Turbine Blades .

Turbine blade manufacture crucially requires the nucleation and growth of precisely controlled microstructures. The grain structure within the turbine-blade super alloy material is frequently described by terms such as ‘equi-axed’, ‘directionally solidified’ and ‘single crystal’. These characterise the grain boundary length and thus ultimately the performance of the turbine blade.

TURBINE BLADES MACHINING

The turbine components manufacturing technologies comprise grinding, broaching and milling with the grinding wheels, grinding with the rasping belts, deburring with the abrasive brushes and eccentric expertise in the turbine blades and blisks machining. (Abrasive Water Jet Machining –AWJM, Abrasive Flow Machining –AFM, Electro-Chemical Machining – ECM, Electro-Discharge Machining – EDM).High-speed cutting (HSC) permits stress-free sculptured machining of the high performance alloys. Its composites being used by aircraft and power-generation manufacturers.

The multi-axes CNC machining centres guarantee high level of shape repetition accuracy in series production.

The modern 5-axes machining centres facilitate machining of the turbine and compressor blade leading sharp edges, trailing edges and tips in one set-up procedure. The centres are equipped with CNC control system with software for NC simulation of the blade aerofoil. The blade root machining method, enabling the machinist to ensure milling operations. Tools on the computer screen and optimize the NC program. However finishes grinding of the blade aerofoil surface have been impracticable on those machine tools. These blades require general hand-polishing to breed the requisite shape and surface roughness.

The machine tool manufacturers

Machine tool manufacturers developed the other type of the machining centres to avoid those disadvantages and to reduce the number of the necessary machine tools by introducing new techniques n milling and grinding.

Nowadays in the different technologies of the turbine blade and vanes removal machining the machining centres (MakinoA99-5XR-CD, Bridgeport FGC1000) is applied by the producers.

These centres were espoused by transformation to crushing and milling the blades with VIPER method (an acronym of Rolls-Royce: Vitreous Improved Performance Extreme Removal), however their main intention were machining with the cutting tools of distinct edges geometry. The innovation integrated lodgings and adjustments to the conditions of grinding: the core spindle, the splatter guards of roller rail linear movements, a cooling medium discharge and filtration unit, an sufficient sort of coolant assortment, equipping the device tool with grinding wheel dressing attachment and with numerically controlled system of the nozzles to convey the coolant unswervingly into the machining region, to work out a appropriate software for CNC control system.

Also See: Digital Security : Protecting your Digital Identity

MANUFACTURING SINGLE CRYSTAL TURBINE BLADE

Different methods of manufacturing are in practice to create single crystal turbine blades. Theses manufacturing methods mainly use the idea of directional solidification, or self-directed solidification. A common method used is the Bridgman method for growing single crystals which uses casting furnace for crystal growth. This process involves a mould that must be firstly made of the blade itself. Molten wax is infused into a clanging mould of the required turbine blade. It is then left to set down.

Eventually it takes the form of the turbine blade after undergoing the proper process. The wax model is then used to make a ceramic cast. This cast is used for manufacturing of the single crystal turbine blades. To add strength to the cast, it is heated at high temperature which increases its final strength. Once the mould is ready for use, the wax is melted out from the inside of the cast. The mould is now filled with the molten form of the nickel based super alloy. The molten super alloy contained within the mould is placed in some type casting furnace. Casting furnance is often a vacuum induction meltingfurnace, which uses Bridgman techniques.